|

Products < Cable < Distribution Cables(Standed-type) (distribution cables ) |

|

| |

| Distribution Cables(Standed-type) |

| |

| Design |

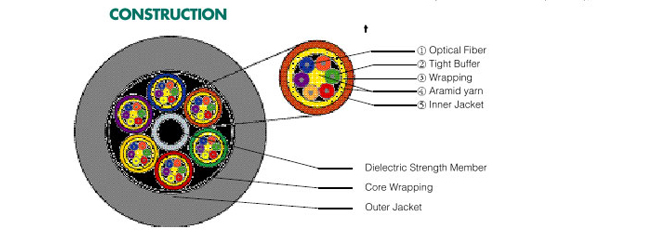

The Distribution Cables shall have fiber count up to 36.

The distribution cable core shall be stranded with several

sub-stranded units (Stranded-Type 4C.5C and 6C).The

each optical fibers are buffered by a protective FR-PVC.

The cable core shall be stranded with two or several units

and surrounded with a layer of reinforcing aramid yarn.

The colored thermoplastic inner jacket(Sub-stranded unit)

is extruded over the aramid yarn.

The sub-stranded units shall be helically stranded in

cable core for survival in difficult pulls and superior

mechanical protection for the optical fibers.

Color-coded (or jacket numbering print) sub-stranded

units are easy to identify for improved cable

management in routing and termination.

Our tight-buffered multi-fiber design with aramid yarn

strength member allows for flexibility and reliability for

use in trunking. LAN and distribution application. Other

designs are also available on request to meet specified

requirments and conditions.

|

| Applications |

The Distribution Cables is a flexible, flame-retardant,

non-metalic cable recommended for use in

telecommunication station between the optical line

system and the fiber frame distribution (OFD). It is also

suitable for data networks (LAN).

• Intrabuilding Backbone

• Trunking, FDDI, LAN distribution

• FRP w Aramid yarn Central Strength Member

reinforce Cable

• Indoor / Outdoor Cable

|

| Features |

• Fiber count up to 36

• Available in single mode and multi-mode fibers

• Highly flexible and light weight for easy handling

• Compact design to save duct or conduit space

• Flame-retardant PVC, Hytrel, Nylon and LSZH butter

• Flame-retardant PVC, FR-PE and LSZH jacket

• FRP or aramid yarn strength member reinforcement

• Easy stripping for quick splicing

• UL-listed riser-rated OFNR (UL-1666), Cable

• UL-listed plenums-rated OFNP (UL-910), Cable

|

|

|

| |

| Cable Technical Data |

Part Number

(Standard) |

Sub-bundies

Unit

Lay-Out |

Jacket

Diameter

(mm) |

Cable

weight

(kg/km) |

Tensile Load

(N) |

Minimum Bending

Radius

(mm) |

Temperature

(¡É) |

Supplied

Length

(m) |

| Installing |

Operating |

Installing |

Operating |

Installing |

Operating |

| DC-SP/PP 04-YL |

1 Unit (4C) |

4.6 |

30 |

600 |

120 |

70 |

46 |

-15~+15 |

-20~+70 |

1,000 |

| DC-SP/PP 05-YL |

1 Unit (5C) |

4.9 |

32 |

600 |

120 |

75 |

50 |

-15~+15 |

-20~+70 |

1,000 |

| DC-SP/PP 06-YL |

1 Unit (6C) |

5.5 |

35 |

620 |

130 |

85 |

55 |

-15~+15 |

-20~+70 |

1,000 |

| DC-SP/PP 08-YL |

2 Unit (4C) |

6.8 |

45 |

660 |

130 |

100 |

68 |

-15~+15 |

-20~+70 |

1,000 |

| DC-SP/PP 10-YL |

2 Unit (5C) |

7.3 |

46 |

660 |

130 |

100 |

72 |

-15~+15 |

-20~+70 |

1,000 |

| DC-SP/PP 12-YL |

2 Unit (6C) |

7.9 |

48 |

1,200 |

240 |

120 |

80 |

-15~+15 |

-20~+70 |

1,000 |

| DC-SP/PP 16-YL |

4 Unit (4C) |

10.2 |

110 |

1,400 |

320 |

150 |

100 |

-15~+15 |

-20~+70 |

1,000 |

| DC-SP/PP 18-YL |

3 Unit (6C) |

10.4 |

120 |

1,400 |

320 |

150 |

100 |

-15~+15 |

-20~+70 |

1,000 |

| DC-SP/PP 20-YL |

4 Unit (5C) |

10.8 |

135 |

1,600 |

360 |

160 |

100 |

-15~+15 |

-20~+70 |

1,000 |

| DC-SP/PP 24-YL |

4 Unit (6C) |

11.5 |

150 |

2,000 |

450 |

180 |

120 |

-15~+15 |

-20~+70 |

1,000 |

| DC-SP/PP 30-YL |

5 Unit (6C) |

12.5 |

190 |

2,500 |

680 |

180 |

120 |

-15~+15 |

-20~+70 |

1,000 |

| DC-SP/PP 36-YL |

6 Unit (6C) |

13.7 |

220 |

3,000 |

680 |

200 |

140 |

-15~+15 |

-20~+70 |

1,000 |

|

| |

| Ordering Information |

Select Fiber Type Select Fiber Type

S : 9/125 SMF (Single mode fiber)

M£º50/125 MMF (Multi-mode fiber)

H£º62.5/125 MMF (Multi-mode fiber)

Select Inner Jacket Materials Select Inner Jacket Materials

H: TPEE (Thermoplastics Polyester Elastomer £» HytrelR)

L: LSZH (Low Smoke Zero ("¤·") Halogen)

P:FR-PVC(Flame-retardant Polyvinyl Chioride)

Select Cable Outer Diameter Select Cable Outer Diameter

02 : Fiber Count |

Select Buffer Materials Select Buffer Materials

N: PA-12 (Polyamid ; NylonR)

H: TPEE (Thermoplastics Polyester Elastomer £» HytrelR)

L: LSZH (Low Smoke Zero ("¤·") Halogen)

P:FR-PVC(Flame-retardant Polyvinyl Chioride)

Select Flame Retardancy Grade Select Flame Retardancy Grade

L : LSZH Type(Low Smoke Zero ("¤·") Halogen)

P : OFNP Type (Frame-retardant Polyvinyl Chloride)

---Indoor Appliction (Thickness. 1.0mm)

E : FR-PE

(Frame-retardant Polyethylene)

---Outdoor Application (Thickness. 1.5mm)

Select Jacket Color Abbreviation Select Jacket Color Abbreviation

EX)BK : Black |

|

♣Printing of outer jacket ( OPTIONAL according to CUSTOMER) |

| |

| Cabled Attenuation |

| Fiber Type |

SMF (9/125)

(Single Mode Fiber)

13.10nm / 1550nm |

MMF(50/125)

(Multi-Mode Fiber)

850nm / 1300nm |

MMF(62.5/125)

(Multi-Mode Fiber)

850nm / 1300nm |

Maximum Attenuation

(dB/km) |

0.40 / 0.25 |

3.5 / 1.5 |

3.7 / 1.5 |

Typical Attenuation

(dB/km) |

0.35 / 0.20 |

2.5 / 0.6 |

3.0 / 1.0 |

|

| |

|

|

|